The benefits of auto-release skips over standard tipping skips

When it comes to forklift tipping skips, there are various types and benefits for your business.

Standard tipping skips have long been the go-to choice for many businesses. However, a new wave of efficiency and safety is being ushered in with the design of auto-release skips.

At Forklift Skip Market, we want you to make the best decision for your company. We will delve into the benefits of auto-release skips over standard skipping tips, helping you choose the best option for your waste disposal needs.

What are auto-release skips?

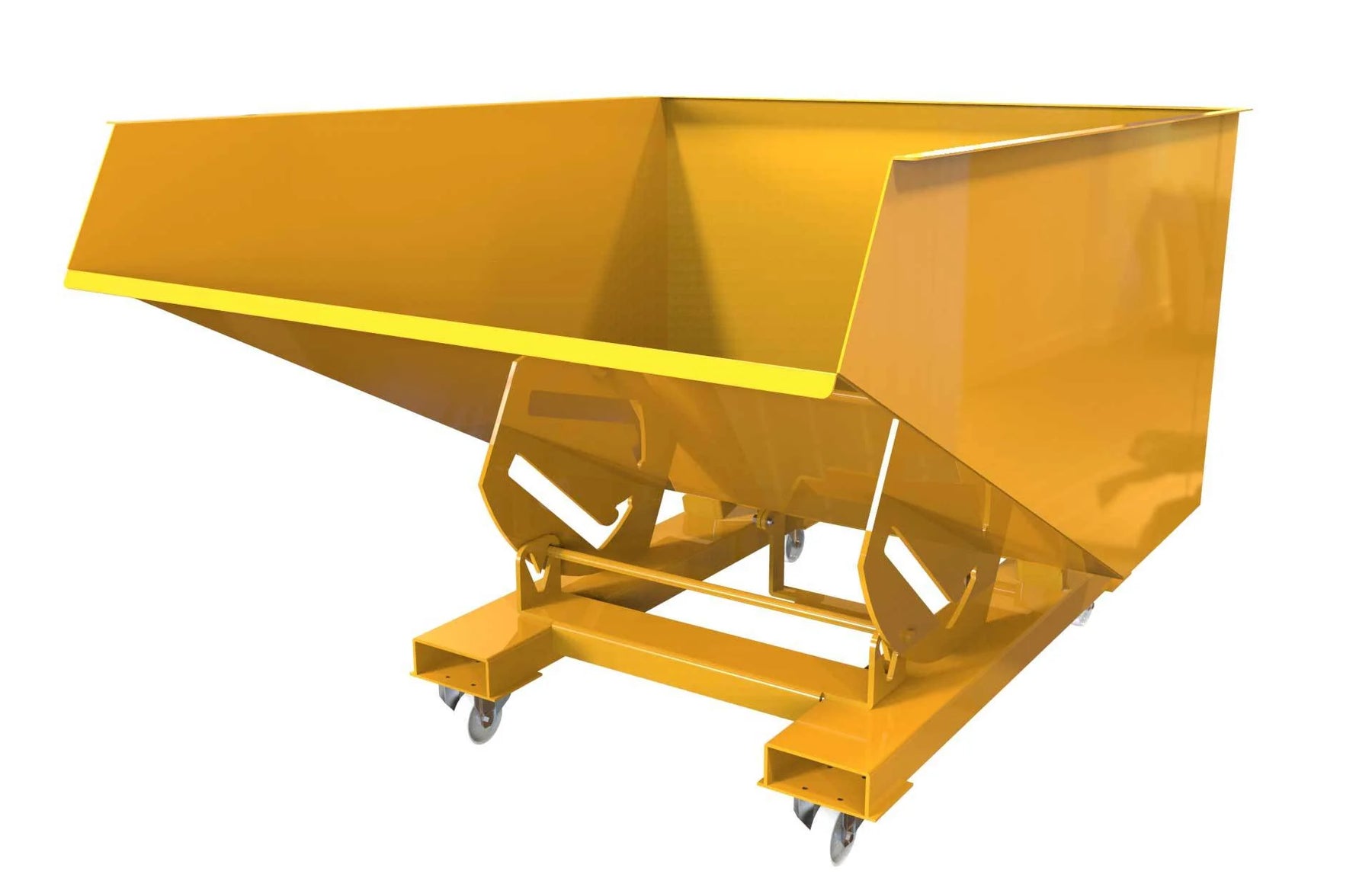

Auto-release skips are waste-handling skips with an advanced automatic-release mechanism. This allows for the auto-release and closure of the skip bottom and side panels, preventing the need for manual loading.

These are designed specifically for holding and transporting various materials, particularly in construction, industrial, and waste management settings.

Their ability to handle a wide range of materials and loads makes them the perfect choice for larger projects.

What are standard tipping skips?

Standard skipping tips are the most common form of forklift skip used in construction, manufacturing plants, and waste disposal facilities.

These are used to store and transport materials and waste, and the ‘tipping’ label refers to how they have to be manually lifted and emptied.

Standard skips are popular due to their versatility and ability to handle a range of materials, from industrial waste to debris.

The difference in their design and construction

Auto-release skips are designed with safety and efficiency in mind, whereas standard skips are made to be simplistic and rugged.

Some key differences include:

Material quality

Both skips are made from high-grade materials such as reinforced steel. However, auto-release skips include thicker steel for additional support.

Mechanical components

Auto-release skips include a combination of hydraulic, mechanical, or pneumatic systems that enable the automated release function.

In contrast, skipping skips are designed for simplicity. They feature robust hinges, manual levers, and cables that allow the skip to tilt easily.

Size and capacity

Auto-release skips are designed to be large enough to handle heavy loads, yet their size is carefully calibrated to ensure the mechanisms function properly without compromising safety.

Standard skipping tips offer more versatility in their size and capacity due to their simpler design. This makes them ideal for small-scale construction projects to large industrial operations.

Enhanced safety features of auto-release skips

Auto-release skips are designed with safety in mind. Various features make this the perfect option for larger projects and their sufficiency helps to decrease task time.

Some notable safety features include:

- Automated release: This minimises the need for direct human contact, preventing the risk of accidents and injury.

- Safety locks and interlocks: These prevent the skip from accidentally releasing the load when transporting the forklift.

- Advanced brakes: The breaking system in some designs automatically halts the release mechanism if a safety issue is detected.

- Load sensing and warning: This alerts the operator of an overloaded or unevenly loaded skip.

Auto-release skips efficiency and ease of use

The simplicity of auto-release skips makes them beneficial for businesses, both large and small, with varying expertise.

These are often operated by the simple push of a button or pull of a lever. Auto-release skips may also have remote controls or automated release sequences, perfect for beginners.

For workers who are constantly on their feet, auto-release skips reduce physical strain, eliminating the risk of injury and fatigue. This can lead to a healthier work environment and fewer personnel needed on-site.

Additionally, the efficiency of auto-release skips can lead to reduced labour costs, less downtime, and lower insurance premiums due to improved safety records.

Environmental benefits of auto-release skips

The precision of auto-release skips can lead to fewer chemical and waste spills, reducing environmental pollution.

Many people use these skips to upgrade their recycling and waste segregation processes, contributing to better sorting and handling of recycled materials.

Due to their automatic nature, less time is spent on unloading, which reduces the need for machinery like cranes and forklifts. This can lead to lower fuel consumption and reduce greenhouse gas emissions.

Invest in an auto-release skip with Forklift Skip Market

At Forklift Skip Market, we specialise in waste management, selling high-quality forklift tipping skips to benefit your business.

With a range of styles and designs to choose from, including telehandler skips to packaging skips and more! we have everything you need for efficient waste disposal.

Browse our wide range of products today at great prices to invest in the ease and efficiency of your business.